The Degassing Function is typically used after injection to remove residual gas, moisture, or to enable foaming inside the mold.

This function is implemented in the Smart Sequencer under the Flexible Chain, using a loop structure with defined delays and degassing steps. Both mold opening and closing movements are executed with adjustable parameters such as velocity, pressure, and position, ensuring precise and repeatable operation.

In addition, the degassing profile provides monitoring features and safety checks. Users can set timeouts for each action to detect abnormal conditions and trigger alarms if limits are exceeded. The ability to configure clamping force independently also offers flexibility compared to the standard mold clamping profile.

1. Activation of option #

- The option can be enabled on option page

2. User screen #

2.1 Setting for profile (Mold Opion Page) #

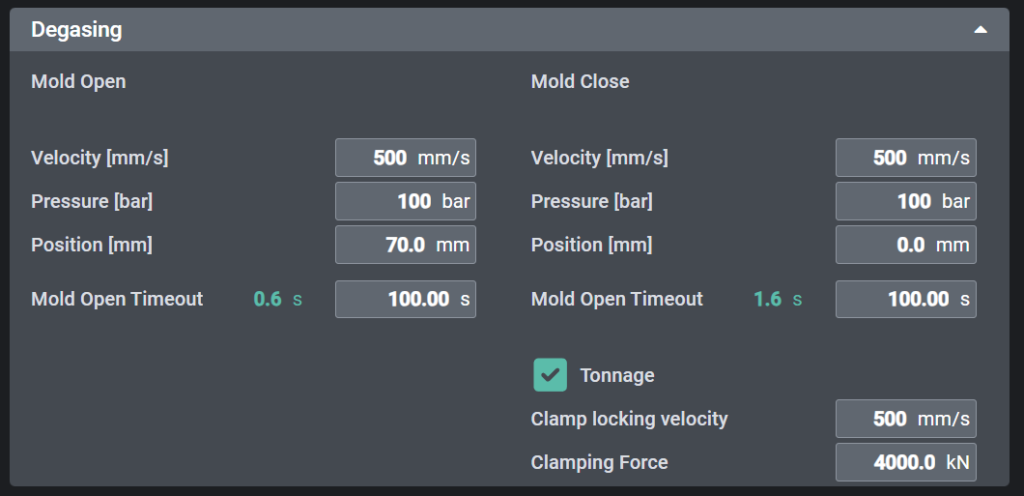

- Function Overview

- The Degassing Profile allows setting the parameters for mold open/close movements during the degassing process.

- Parameter Settings

- Velocity [mm/s]: Defines the speed of mold opening and closing.

- Pressure [bar]: Controls the hydraulic pressure applied during the operation.

- Position [mm]: Sets the target mold position for opening/closing.

- Operation Characteristics

- Degassing is a simple operation and runs with a single-step profile.

- Tonnage Build Option:

- A checkbox allows enabling or disabling the tonnage build during mold closing.

- Unlike the standard mold clamping profile, it is possible to select a different clamping force.

- Monitoring and Safety

- Operation Monitoring Time (Timeout):

- A monitoring time can be set for both mold open and mold close operations.

- If the cycle exceeds the set monitoring time, an alarm will be triggered to ensure safety and process reliability.

- Operation Monitoring Time (Timeout):

2.2 Setting for sequencer #

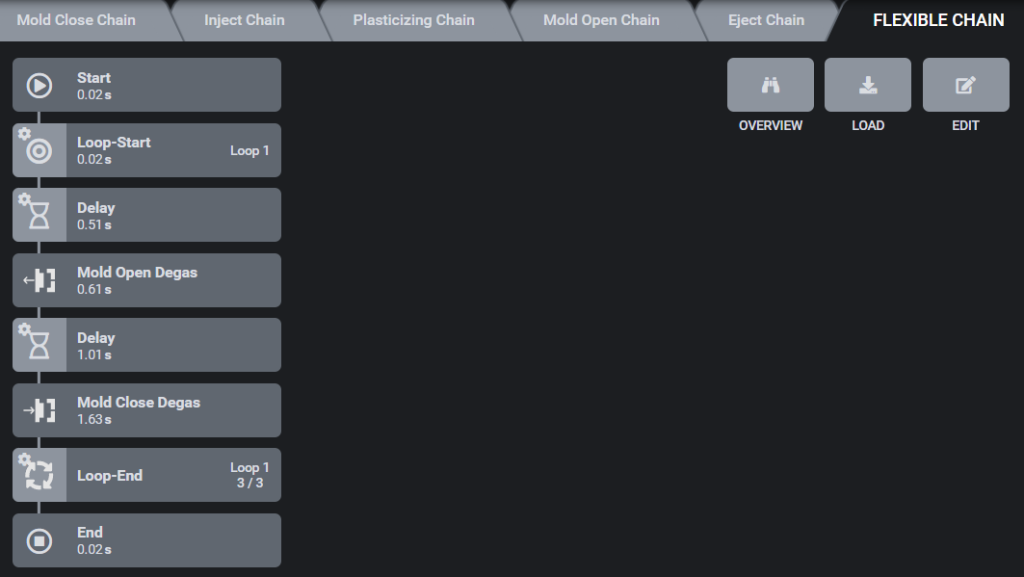

- Function Definition

- This function must be defined within the Smart Sequencer.

- The sequence is configured under the Flexible Chain, as shown in the diagram.

- Sequence Configuration

- The sequence operates with the following steps:

- Start – Initializes the chain.

- Loop-Start – Begins the loop for repeated operation.

- Delay – Adds waiting time between actions.

- Mold Open Degas – Executes the mold open degassing step.

- Delay – Additional waiting time before closing.

- Mold Close Degas – Executes the mold close degassing step.

- Loop-End – Ends the loop cycle (repeat count can be set).

- End – Terminates the chain.

- Key Components

- Mold Open Degas / Mold Close Degas: Core steps for the degassing operation.

- Loop Start / Loop End: Used to define and repeat the degassing cycle.

- Delay: Used to insert a time interval between mold operations.

- Enabling / Disabling the Function

- The Flexible Chain can be deactivated by setting it to Disable Always.

- When disabled, the degassing sequence will not run.

3. Sequence Operation Result #

- Mold close and buildup tonnage

- Injection

- Degassing sequence start

- Start Degasing

- Delay 0.5 s

- Mold open (70 mm)

- Delay 0.5 s

- Mold close (0 mm)

- Clamping force build-up (up to 4000 kN)

- Delay, then mold open again

- Repeat according to loop setting

- Degassing sequence end